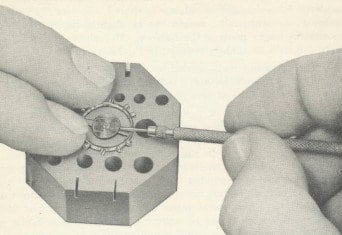

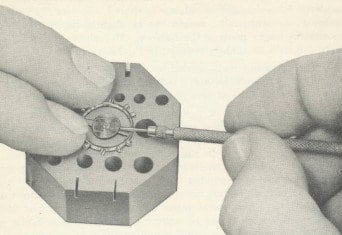

The balance wheel must be poised after it has been trued. In closely rated position watches, such as railroad grade, poising of the balance is of utmost importance in order to obtain fine timing results. A balance that is out of poise will affect the arc of motion while running. A heavy point at the bottom of the balance wheel, when held in a vertical position, will show a losing rate in the first half of a 24-hour period or during its long arcs of motion. If the heavy point is at the top of the balance wheel, it would show position variations in the reverse. It is well to remember that while poising a balance, reducing the weight will result in a gaining rate. Increasing the weight will result in a losing rate, so, therefore, the mean time rate should be considered before weight of balance is altered. In case the rate was a gaining one continually, weight can be slightly increased directly opposite the heavy point of the balance. If it showed a losing rate, weight can then be slightly reduced at the heavy point. The necessary tools needed for poising a balance are: poising tool, balance screw undercutters, balance screwdriver, screw-head file, balance screw scale, assortment of timing washers, and balance screws. {I. The actual work of poising is accomplished by placing the balance wheel on the poising tool (or truing calipers if poising tool is not available) so as to have the most extreme end of each pivot supported. This is done with the rollers attached and hairspring removed, and with balance wheel in a vertical position. In this manner, the .balance wheel is suspended freely and force of gravity will cause the heaviest part of the balance rim to turn to the lowest point. The screw which is at the lowest point indicates the heavy part of the balance, so this screw must be undercut. Hold balance firmly and remove this screw. Place screw in undercutters of its approximate size and undercut slightly by turning the screw. Replace screw and check. If after undercutting a screw, the weight shifts to the opposite side of the balance, it shows that too much weight has been removed. A balance wheel which is badly out of poise will indicate such an error by the heavy screw falling rapidly to the low point. In a case of this type, it is advisable to add a timing washer to the screw opposite the heavy screw. To undercut the heavy screw would require removing too much weight. This will also maintain the original weight of the balance as nearly as possible. Another important factor is, if the balance wheel is supplied with timing screws, their position from the balance rim should be noted. If they are turned out so that very few threads remain, it is advisable to add timing washer to the light side of the balance when poising. This will allow the timing screws to be turned inward during the timing process. However, if the screws are turned in close to the balance rim, weight may be reduced from the heavy side, allowing the timing screws to be turned outward during the timing process. The methods which can be used to reduce weight are: The screws may be undercut, the screw-head file may be drawn through the screw slot slightly, or the heavy screw can be removed and replaced with one of the same weight as the opposite screw. To increase weight, add timing washers to light screw, or exchange light screw for one that is of a weight equal to its opposite screw. If the work of poising appears satisfactory, a final test may be applied by turning the balance wheel slowly with a camel’s-hair brush and stopping it at each quarter of its circumference, beginning with

the roller pin at the top. To have accomplished a good job of poising, the balance wheel should remain at rest and at the place it has been stopped. For a finer position adjusted watch, the balance wheel may be tested at every eighth part of its circumference. If the balance wheel remains at rest at all eight places it is stopped, it is considered in perfect poise. While testing the balance, if it is found that atsome points it does not remain at rest, work must be resumed until the error has been eliminated.