In order to replace a glass crystal in an Elgin watch with a genuine Elgin crystal, the jeweler and watchmaker should know the correct procedure for ordering and fitting the crystal.

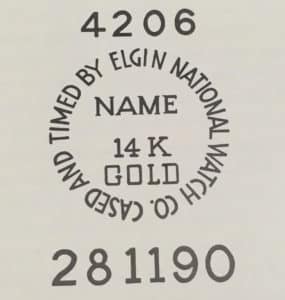

For some time now all Elgin cases have had the case number stamped in the back of the case. For example:

The numerical coding (4206) located above the circular stamp “Cased and Timed by Elgin National Watch Co.” identifies the case. In all cases, except diamond set cases this numerical coding consists of four numbers. In diamond set cases, the numerical coding consists two numbers. In ordering a crystal for a watch case from your material dealer, simply refer to this numerical coding or case number and specify that the crystal is for an Elgin case.

The number (281190) located below the circular stamp “Cased and Timed by Elgin National Watch Co.” is the case manufacturers’ number and is not to be mistaken for the case number. Always remember that the case number has four digits in diamond set cases. In a few models the case number is located inside the circular stamp or in some other location, but in most models it is located above the circular stamp.

When assembling the new crystal to the case bezel, make sure the old cement has been cleaned out of the crystal groove. Now press the glass crystal into position in the bezel. If the crystal is the bent glass type, it should fit the bezel with a “snap-fit,” If the crystal is the molded type with side walls, it should fit the bezel with a slight friction. If a molded crystal were fit to a bezel with a “snap-fit,” the crystal would be under excessive tension for this type or crystal and it would eventually break.

Genuine crystals, obtained by ordering by case number from your material dealer, should fit the bezel with the correct amount of “snap-fit” or “friction fit.” However, in some instances, because of manufacturing variations, a slight “touch-up” on a small grinding wheel may be necessary. The technique is simple and with a little practice you soon will get the feel of it.

It is important that the edge of the crystal, after being ground, be polished both for appearance and easy snap fit, thus eliminating any danger of chipping the sharp edge when pressing crystal into place. The polishing is done with a felt wheel to which any polishing material may be applied. We recommend a mixture of three parts pumice stone No. 3 and one part putty powder applied wet with water.

After the jeweler or watchmaker is sure the fit of the crystal in the bezel is correct, the crystal should be removed from the bezel. Now, apply a good crystal cement all around the crystal groove in the bezel. Snap the crystal in place and again apply the cement around the top to the crystal at the joint between the crystal and bezel. Immediately, wipe off all excessive cement with a soft lint free cloth. This procedure will give a tight fitting crystal which is sealed against dust.