From 2020, Swatch Group will be allowed to stop supplying third party clients with ETA movements. For Sellita and Soprod, the two biggest alternative manufacturers of entry-level and mid-range Swiss made calibres, the stakes are high. Probing the heart of Swiss watches.

A number of movement specialists attended the most recent EPHJ trade fair, which took place in Geneva in June, including Technotime, Vaucher Manufacture and Dubois Depraz. However, two were notable by their absence: Sellita and Soprod, the biggest producers, in terms of volume, of Swiss made alternatives to ETA’s workhorses. Historically, according to various estimates, the Swatch Group subsidiary accounts for almost three-quarters of the standard mechanical movements produced in Switzerland (i.e. 5 to 6 million units). Very few alternatives exist for entry-level and mid-range watches, particularly at less than 200 francs per unit. Andre Colard, co-founder of the Swiss microtechnology fair, which this year brought together around 825 exhibitors from the watchmaking, micromechanics and medical technology sectors, explained: “Soprod was there last year. As for Sellita, at the moment they have no particular need to advertise.”

Perhaps the two manufacturers had other things on their mind. There is little doubt that their eyes are firmly fixed on a certain date: 2020. They have been under a great deal of pressure in recent years. After numerous steps forward, reversals and re-evaluations, last October the Competition Commission (Comco) and Swatch Group finally reached an agreement which in effect affects the entire watchmaking industry. According to the exact terms of the deal, “the obligation to supply mechanical movements will remain in effect up to 31 December 2019.” In 2014/2015 ETA is to deliver 75% of the average number of units sold between 2009-2011; this drops to 65% in 2016/2017 and 55% in 2018/2019. The company is also obliged to treat each of its clients “in an equal fashion.”

Race against the clock

Sellita General Manager Miguel Garcia expressed his relief. “Comco’s decision has given us a breathing space. All clients will be treated on an equal footing, and we are one of them.” In 2013, the La Chaux-de-Fonds company, which employs 500 people in Switzerland and Germany (compared with 300 a year ago – this gives an idea of the expansion under way), supplied 1.4 million movements: 800,000 Sellita calibres and 600,000 ETA calibres that were assembled and resold. But Swatch Group has already started to reduce supplies to Sellita: back in 2011 the company reported total production of 1.6 million movements.

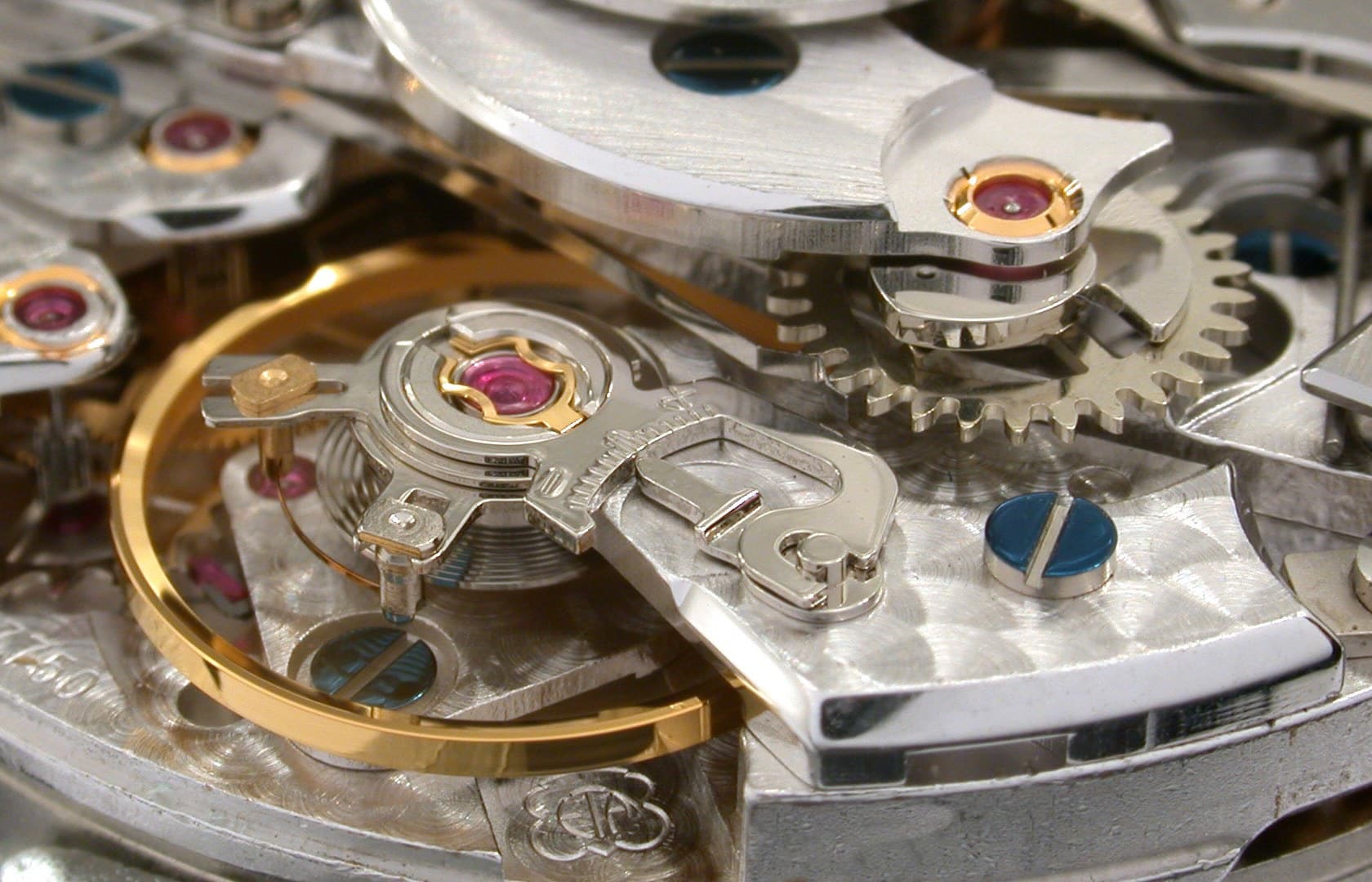

The race against the clock has begun: “Our aim is to replace the movements we buy from ETA with Sellita calibres by 2019. We therefore need to expand our in-house production by at least 600,000 movements in that time.” The company nevertheless remains dependent on the Swatch Group for its escapements – the components that regulate the watch, including the balance and balance springs. Here too, Miguel Garcia has reason to be relieved: Comco has ordered Swatch Group’s Bienne-based subsidiary Nivarox to continue deliveries, on the grounds that it does not have the necessary “visibility” to establish a timetable for reduction. Nivarox has an even greater monopoly than ETA, producing virtually 90% of the parts used by Swiss watchmakers. Sellita, which supplies around 250 brands, will be focusing its efforts on these strategic components, for in-house calibres. “We are putting in place in-house production of escapements. But it is a very lengthy process.”

Sellita’s SW calibres are based on the features (dimensions and functions) of those ETA movements that are now in the public domain. The company has thus been able to develop direct alternatives to the Swatch Group’s best-sellers: the SW 200 can be used in place of the historic ETA 2824; the SW 300 is a clone of the ETA 2892; and finally, moving up the range, the SW 500 is a replacement for the 7750 chronograph movement. Many Swiss watchmakers use these models as a base movement, personalising them with complications. In the space of a decade, under the impetus of chief executive and owner Miguel Garcia, Sellita has built itself a reputation as a credible alternative and a worthy rival, from both a qualitative and a quantitative point of view, to ETA. It remains to be seen whether, by producing its own escapements, the firm can remain competitive on price.

A movement “Bubble”?

Trailing far behind Sellita in terms of volume, with just over 100,000 movements produced in 2013, Soprod has the advantage of no longer depending on the Swatch Group for its escapements. “Movement production is not an easy sector to be in, particularly when you decide not to copy ETA! We make everything in-house, except for the jewels, barrel springs and shock-absorbers,” explained Gerald Roden, managing director of Swiss Festina Group. Headquartered in Reussilles (JU), Soprod can source components from other subsidiaries of the group, icluding MHVJ in the Vallee de Joux, for escapements, and MSE in Muriaux (JU) for balance springs.

“We are experiencing growing demand; new clients turn up almost every week,” he confirmed. Nevertheless, caution still seems to be the rule in the watchmaking world, as far as the robustness of the alternatives to ETA are concerned. Soprod is taking this in its stride: “Many clients want to visit our workshops to make sure that everything is indeed made in-house and on-site!”

Soprod’s SOP A10 movement is an alternative to the ETA 2892. Because of its lower production levels the company cannot, however, compete directly with ETA or Sellita on price.” The A10 is available at 180 francs per unit. We don’t offer different quality levels, we are equivalent to ETA’s “Top” standard.”

The Festina group, which has around 400 employees in Switzerland, uses only a small fraction of its movements – 7% to 8% – for a “house” brand Perrelet. “Candino, on the other hand, uses ETA or Ronda quartz movements.” The vast majority of production goes to third-party clients, including some major groups. Gerald Roden confirmed: “We have many loyal clients, but they are not too keen on being talked about by their subcontractors…” Festina Switzerland is embarking upon a phase of rationalisation, which will involve consolidating certain activities in Bienne. Given that the company is not dependent on the Swatch Group, its boss has an understandably different reading of the Comco agreement: “This decision favours those brands that already had a quota with the Swatch Group. In a way, Comco is “sponsoring” Sellita, which can continue to be supplied with escapements because it already has a contract with ETA. Because we make everything ourselves we have higher costs.”

For Gerald Roden, the impact of Comco’s decision in the long term is difficult to evaluate.” On the one hand, groups are now looking for alternative suppliers, which represents an opportunity for base calibre manufacturers like us.” But the MD paradoxically fears a movement “bubble”: a rather surprising scenario that flies in the face of current fears that are crystallising around the prospect of a shortage.” All movement users have over-bought, in anticipation of a reduction of deliveries by Swatch Group. There is always the risk of a slowdown in the watchmaking industry,” he said. “We won’t begin to see how things turn out until 2019, when supplies reach their final reduced level.”

Alternative for balance springs

Technotime shares this view. Managing director Laurent Alaimo noted: “We could just as easily be looking at a feast as at a famine: if ETA decides to loosen the screws tomorrow, all the alternative projects will be in difficulty.” Based in Les Brenets (NE) and with 25 employees, the company produces 12,000 movements per year. But it also advertises a production capacity of 300,000 balance springs, for around ten clients, making it one of the rare alternatives to Nivarox – albeit on a far smaller scale (the Swatch Group subsidiary produces around seven million a year…).

While Technotime’s TT 651 and 651-24H modules are built on an ETA 2892 or equivalent base movement, the 718 (manual), 738 (automatic) and 791 (tourbillon) series are in-house movements. Nevertheless, Laurent Alaimo does not consider his company a direct alternative to ETA. The architecture of its products (twin barrels, five-day power reserve) and the volumes it supplies do not allow it to compete on price. In addition to its modules, the company offers manufacture movements starting at 575 francs. Tourbillons, on the other hand, cost up to 20,000 francs. It’s a wide price range.” Our target audience is precisely those clients who don’t want a standard movement. We work with those watchmaking development offices that were turned away by the Swatch Group. Our manual and automatic calibres are increasingly in demand by those brands that want to differentiate themselves from the ETA label.”

Technotime’s MD believes that the production of hairsprings could represent “an interesting growth vector” for the company, particularly for those brands that are planning to produce their own in-house calibres, independent of the Swatch Group. But, given that the company has already mastered this strategic component, why not, in light of Comco’s decision, go for the mass-market movement? Laurent Alaimo does not rule out this possibility. “Partnerships could be considered, both upstream and down. But securing movements at wholesale prices requires major investment. And with a project of this scale it is difficult to generate a consensus among the brands.”

He points out that many projects for alternatives to ETA calibres are currently under discussion in the watchmaking industry, some with a view to more vertical integration, and others with a collaborative element. But he also notes: “We are in contact with some of those involved, but the figures mentioned are extremely high, in the order of 20 to 50 million francs. And when you are looking at producing a calibre from A to Z, you quickly realise how few options there are for certain critical components. Moreover, there seems to be relatively little input from the end clients in these projects.” Like Gerald Roden, Laurent Alaimo also notes that the reduction of supplies by ETA has led to a great deal of pre-ordering. “We estimate that watchmakers and assemblers are holding two years’ worth of stock.”

Integrated production

At Vaucher Manufacture it has not yet reached the point where they are considering going down-market to position themselves as an alternative to mass-market calibres: “To compete with ETA’s best-selling movements, we would have to produce hundreds of thousands of units just to pay for the infrastructure investment,” points out managing director Jean-Daniel Dubois. Nevertheless, like Technotime, the manufacture is one of the rare companies outside the Swatch Group capable of producing balance springs. And much more besides: via the subsidiaries of Manufactures Horlogeres de La Fondation de Famille Sandoz (MHF) – Atokalpa, Elwin, Quadrance, Habillage, Les Artisans Boitiers – Vaucher has access to dials and cases. Ninety-five per cent of its movements are produced in-house: “The remaining 5% comprises the rubies, barrel springs and shock absorbers.”

Such integrated production appears to work. Offering a price range between 700 and 4,500 francs, the manufacturer has significantly increased movement deliveries, from 6,000 calibres two years ago to 22,000 today. Vaucher Manufacture produces five families of “VMF” calibres. Our aim is to reach 35,000 units five years from now. At the moment, 60% of our production goes to Parmigiani Fleurier and Hermes. Our external clients include Harry Winston, Richard Mille and Corum.”

Companies in the MHF group, which employs 450 people, are gradually opening up to third-party clients, particularly the smaller brands. Last year Vaucher Manufacture Fleurier launched a “Private Label” initiative, with prices starting at less than 1,000 francs, and a minimum order of just 25 units. This trend is nevertheless coming up against the ever-stronger tendency of brands to become manufactures in their own right.” This verticalisation could have an impact on us, and the market is certainly getting tighter. Regulating organs nevertheless remain a lucrative niche.” It is worth noting here that the Concepto group of La Chaux-de-Fonds is also positioning itself as an alternative to the Swatch Group for escapements: you may remember that in 2012 its CEO, Valerien Jaquet announced a target of 400,000 deliveries per year.

A long shot

Despite the obstacles, some smaller companies are trying to join the ranks of Sellita and Soprod as alternatives for entry-level movements. This is the case of Horlogerie Schild, which was present at EPHJ with its new S280 calibre: a rival, it hopes, to the best-selling 2824. The movement is not a clone of ETA; it is inspired by a calibre of Chines origin. “Our Soigne movement meets the requirements of “Swiss made”, with 60% of Swiss value. It is assembled in Orpund (BE). Our Chronometer, Soigne+ and Top movements, which have a Swiss escapements, correspond to 80% of Swiss value,” confirmed CEO Lihua Mao. Like others that have come before, the company wants to graduate from assembling movements to designing its own calibres.

“We started production a year ago and are in a position to supply 15,000 midrange movements this year to Swiss watchmakers. We are aiming for 50,000 units by 2015.” The Berne-based company, which has eight employees but intendsto double that this autumn, offers its entry-level movement at 90 francs. The COSC chronometer comes in at 158 francs. “We are a little more expensive than ETA, because we have nowhere near the same production volumes. But we represent an alternative for clients who don’t have access to the Swatch Group, and who are looking for Swiss made calibres.”

Leschot (Felsa) of Neuchatel has also announced a new movement based on the ETA 2824. Starting price: 125 francs. “It took us three years to develop the movement. We bought 85% of Technotime France, and brought production into line with current trends. Today we are shipping a few thousand units, to brands such as Camy,” said managing director Miro Bapic, who attended this year’s EPHJ trade fair. He makes no secret of his ambitions: 500,000 units withing five years. Will these be for Swiss clients? “No, the great majority of our clients are in the Middle East and the Far East. They are prepared to order large quantities. In Switzerland, people come to me for series of 5 to 10 movements…”

Florian Serex, formerly of ETA and Vaucher Manufacture, has a great deal of experience in watch movements. These days he works as a consultant, and is involved in an ambitious project entitled K1 (for Kaliber 1), under the aegis of Bienne watch component manufacturer Momoplus. “It’s not an ETA clone. We have developed an 11½ calibre with a width of 4.95 mm. It can be made in 18 different configurations, and because the final phase of assembly takes place from the dial side it offers great flexibility and the agility to respond quickly to the demands of the market.

The movement can be equipped with a small or large date at 3 o’clock, power reserve at 6 o’clock, and small seconds or central seconds at 9 o’clock. “The brand sources its hairsprings, a strategic element if ever there was one, in Germany. Why take on such a risky project, even if the foundations were laid five years ago? “We realised at Momoplus that some clients were struggling to access movements. Most of them said they weren’t worried… But if they couldn’t source calibres, there was a significant risk that these clients would disappear!” Three hundred examples of the Series 0 are currently being manufactured to equip both Horage watches (a brand that is part of the extensive Momoplus galaxy), and also for its first third party clients.

Target price: around 250 francs each. “Our business model is open: we could sell the project in its entirely, hand it over to a client or bring in partners.” But the sums at stake and the time constraints give pause. “We’re looking at a minimum of 25 million francs over seven to eight years to guarantee solid industrial development. Many have already tried, and lost their shirts,” admits the project chief, well aware of the challenge he faces. “For the Series 0, we initially wanted to produce 5,000 movements this year. But we needed to find the financing. In theory we should reach that production level next year. 20,000 the following year, and 40,000 units the year after. If everything goes as we hope it will.”

Migration to Sellita

In La Chaux-de-Fonds, La Joux-Perret (bought in 2012 by Japanese group Citizen, which produces the famous line of Miyota calibres), continues to transform best-selling ETA movements such as the 2892 and the 7750, as well as the Sellita SW300 and SW500 movements. The company does not develop its own entry-level calibres. “We do nevertheless provide alternatives to ETA movements such as the 7753,” notes CEO Frederic Wenger. Following Comco’s decision, the firm hopes to use more Sellita movements.

Another player in the movement business, Dubois Depraz, is continuing a family tradition that goes back more than a hundred years. The chronograph specialist based in the Vallee de Joux focuses on modules and complications. The SME, which employs 330 people including at its Arch (BE) profile-turning subsidiary DPRM, works with movements bought directly from ETA, Sellita and Soprod, as well as with its clients’ own calibres. “We supply all the major groups without exception with complicated movements, to the tune of 100,000 units per year,” explains co-director Pascal Dubois, who represents the fourth generation at the head of the company.

Chronode of Le Locle aslo specialises in complications. But it also offers three in-house calibres. “We can’t, however, be defined as an alternative to ETA: our calibres are customised, we supply between 1,000 and 2,000 movements per year and our prices start at 1,500 francs,” notes founder Jean-Francois Mojon. The company, which employs nearly 70 people, has strategic elements covered via its subsidiaries DMP (profile-turning) and CHL (decoration).

But what if the answer, in terms of finding alternatives to ETA, were to come from the watchmaking brands themselves? In the wake of Comco’s decision, many watchmakers are developing their own infrastructure in a bid to become self-sufficient. They could also supply third parties. We contacted watchmaker Maurice Lacroix, who said that they already supplied their calibres to outsiders “on a small scale”. Eterna, which was bought in 2012 by China Haidian, intends to open up sales of its 39 family of movements to third parties as an alternative to the ETA 7750.

The Granges-based company is taking this new departure, and the launch of its “Eterna Movement” unit, very seriously. “For us, it’s a kind of return to our roots: we have a long history in movement design. In the early days, in 1932, ETA was a division of Eterna,” notes Samir Merdanovic, head of the new unit. “We began producing our own calibres again just fifteen years or so ago, on a small scale and solely for internal use. However, we realised that it was too expensive to make our own calibres unless we could sell them to third parties. Hence the creation of Eterna Movement three years ago.”

Preliminary discussion with third parties began just this spring. “Several brands have expressed an interest. This year, we will produce a total of 5,000 movements. Again, the Eterna brand takes priority.” Around 88 modules are available on the base calibre 39, which costs 200 francs. The GMT comes in at 260 francs and the chronograph at 500 francs. “We represent a good 100% Swiss made alternative. We hope eventually to produce 150,000 to 200,000 movements a year.”