The need for precise watches used for the navigation at sea was a driving force to improve the construction of the balance wheel.

Already in the year 1753, a compensating balance was used in the famous H4 of the Englishman John Harrison. It was gradually improved by later watchmakers, like the French horologist Pierre LeRoy or the Englishman Thomas Earnshaw.

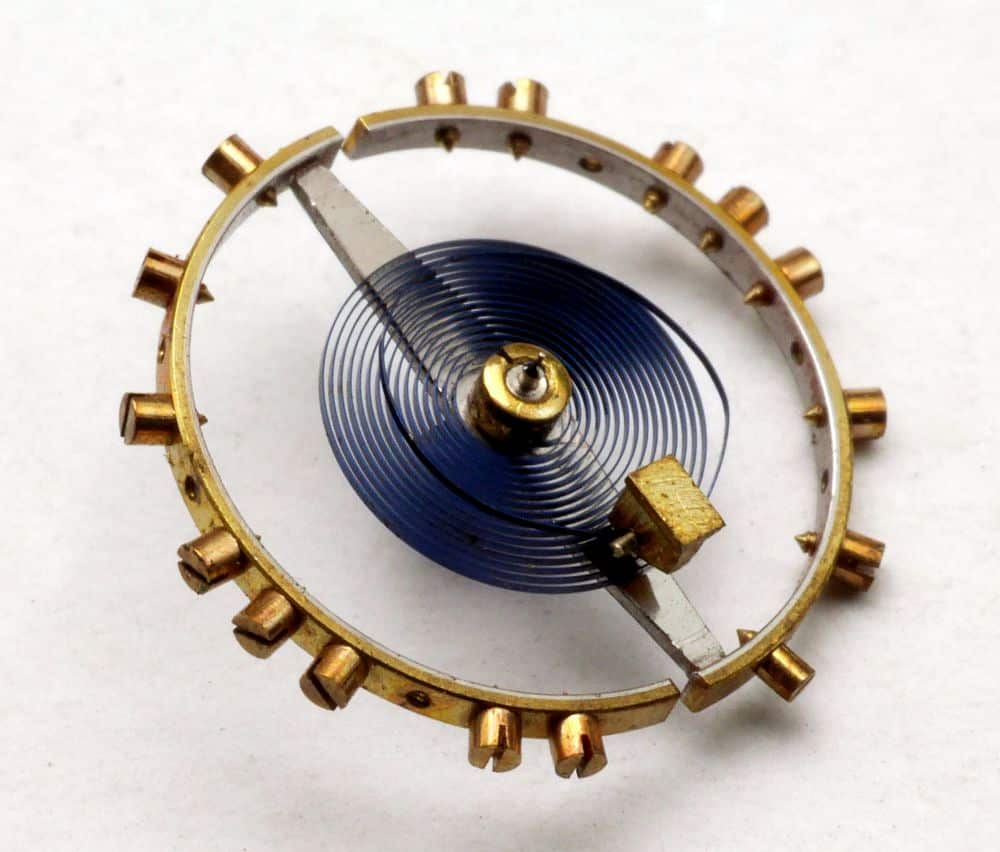

Temperature is an element influencing the beat of a watch, causing an expansion or a contraction of the balance wheel. Most of this problem has been solved with the upcoming of the bi-metallic compensating balance. The outer rim of the balance, which is divided into two parts, is a sandwich layer of steel and brass, which react differently to temperature changes (the thermal expansion of brass is grater than that of steel).

A compensating balance is mostly combined with a screw balance. The screws around can be adjusted to cope with possible imbalances. The latter construction has actually become superfluous today, due to better materials used and parts made with higher precision. They are nevertheless still made this way in today’s high-grade mechanical watches, as this is seen as a sign of quality in watchmaking.