Historical materials and “new materials”

Ever since the dawn of mechanical watchmaking, its base materials have been copper alloys and ferrous materials. As evidenced by the astrarium completed by Giovanni de Dondi in 1386, the combination of iron or steel pinions and brass wheels appeared early on for tribological reasons.

Watchmakers realised from the outset that the materials required to build the first horometers with a mainspring (records of which date back to between 1365 and 1400) had to meet the increasingly numerous and complex imperatives of implementation (cutting, forming, machining), operation (elasticity, resitance to friction, abrasion and ageing) and environment (such as a low factor of thermal expansion in the case of temperature fluctuation, or resistance to corrosion).

Clocks and watches which they could never have lasted more than 700 years. Empirical in its early days, the art of metalworking progressively became a subtle and complex chemistry that watchmaking turned to its own advantage, just as it did the progress of science and knowledge.

In recent years, new materials such as titanium or aluminium-based alloys, silicon and Liquidmétal® have made their debut on the horological stage. Around the turn of the new millennium, the larger size of watch cases and the development of metal wrist strips prompted watchmakers to seek out the lightest materials available.

ALUMINIUM – In 1821, near Baux-de-Provence (France), Pierre Berthier discovered a mineral ore containing 50-60% of aluminium oxide. The process of reducing the ore using sodium proved so costly that the value of the resulting aluminium attained that of gold. At that period, the metal was used exclusively for luxury jewellery and other items for the court of Napoleon III and the elite classes.

From 1886, thanks to a less costly production process using electrolysis, the market of kitchen utensils was opened up to aluminium. Although pocket watches have been made entirely in this metal, only aluminiumtitanium alloys, which are both extremely light as well as hard, are used to obtain a fundamental component of several high-tech, anallergic ceramics that are resistant enough to abrasion to meet watchmakers’ needs.

BRASS – Alloys of copper and zinc, known since prehistoric times, were used in the Middle Ages to massproduce copper and brassware items. Easy to machine, they are traditionally used to manufacture base plates, bridges and other components and bearings for clocks and watches. As brass is inexpensive, the cases of the first affordable watches were made in this alloy.

BRONZE – This alloy of mainly copper and tin known since the second millennium BC has the advantage of being hard and capable of being cast. This is why it is used to make bearings and friction parts. It has the disadvantages of being a good conductor of heat and heavier than steel.

It smells unpleasant in contact with sweat and can cause allergies, which is why it must be treated if used to make wristwatch cases. When alloyed with beryllium, it becomes almost as hard as steel, in which case it can be used to produce balance wheels.

COPPER – Alloyed with beryllium (formerly called glucinium), it offers the best mechanical properties of all the copper alloys in terms of hardness, resistance to corrosion and low coefficient of thermal expansion. Beryllium-copper alloys are therefore tending to replace tempered steel in springs, balance wheels and hands.

Cupronickel alloys, sometimes called “white copper” and traded in the past under the names of Alpacca, Argentan and Minargent, are particularly resistant to corrosion, wear and salt water. They can be used to manufacture bridges, wheels and hands for water sports watches.

GOLD – This metal, a symbol of the sun, has been popular since Antiquity. It has been used in spring watches and clocks since they were first invented, either in solid form or gold plate. Naturally pale yellow in colour, or green in the case of electrum, it can be coloured by adding other metals:

Yellow gold: 75% gold + 12.5% silver + 12.5% copper

Pink gold: 75% gold + 6% silver + 19% copper.

Red gold: 75% gold + 4% silver + 21% copper. This is particularly prized for repeater and chiming watches.

White gold: 75% gold + 10% silver + 15% palladium. It is frequently confused with grey gold.

Grey gold: 75% gold + 12.5% nickel + 10% copper + 2.5% zinc.

Green gold: 75% gold + 24% silver + 1% cadmium. This occurs naturally and is called electrum.

Purple gold (also called amethyst gold or violet gold): 75% gold + 25% aluminium. The alloy may contain small amounts of silver and copper.

Blue gold: 75% gold + 24.4% iron + 0.6% nickel. Its blue colour is obtained by heat treatment which oxidises the iron atoms on the surface of the metal.

The composition of the alloys is indicative only and is provided for 18-karat gold. It differs according to the percentage of pure gold and the desired shade. Other hues also exist, such as a salmon-pink gold (an alloy of gold and platinum) and a yellow-green gold (an alloy of gold and zinc).

Combining golds of different colours in both the watch case and bracelet allows for the creation of innumerable geometric or figurative designs. Designs marrying yellow, white, red and green were especially popular during the final third of the eighteenth century.

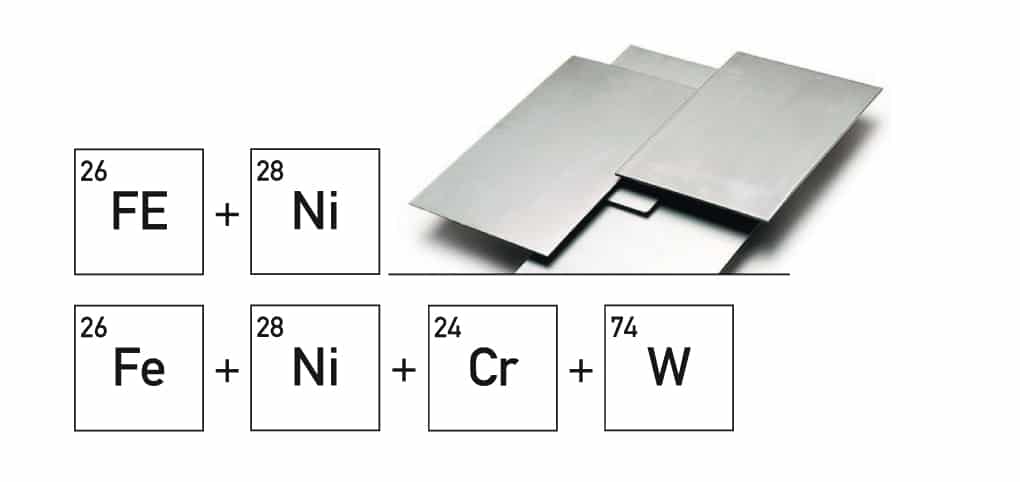

INVAR AND ELINVAR – During the course of his career, physicist Charles-Edouard Guillaume (1861-1938) developed, manufactured and tested nearly 600 alloys.

Among those with a very low expansion coefficient, Invar (iron + nickel) and Elinvar (iron + nickel + bromine + tungsten) date from 1896 and 1913 respectively. He used the former to manufacture the balance wheel that bears his name.

Also called an “integral” balance wheel, it eliminated the middle temperature error, a residual defect caused by the thermal compensation of watch balance wheels between 4°C and 39°C. Elinvar, with its invariable elasticity coefficient, was used to produce compensation balance springs, from which those made in Metelinvar®, Durinval® and Nivarox® are derived.

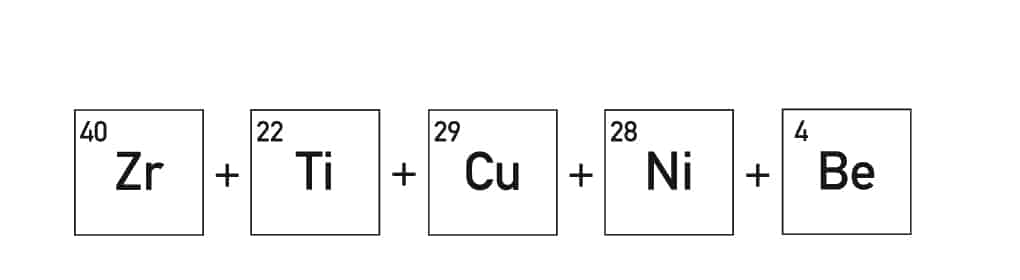

LIQUIDMETAL® – The trade name of a series of alloys developed by the California Institute of Technology and launched on the market in 2003. Composed of zirconium, titanium, copper, nickel and beryllium, its melting temperature is half that of conventional, titanium-based alloys. Once cooled, it is three times harder than stainless steel.

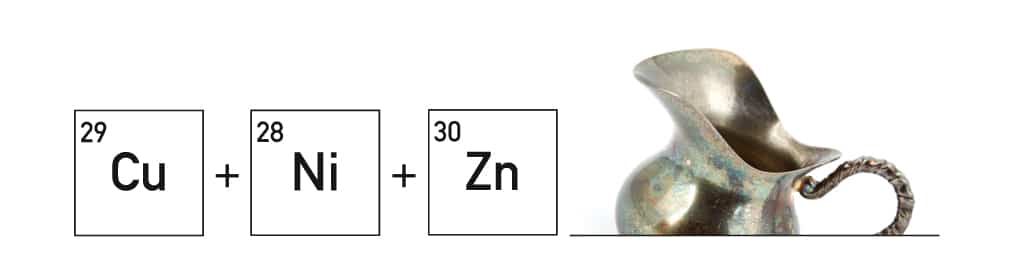

NICKEL SILVER – Long known in China under the name of “baitong”, this alloy was rediscovered by Maillot and Chorier who named it “maillechort”. Patented in 1827 by Philibert Maillot, it is an alloy of copper, nickel and zinc. Since its mechanical characteristics are superior to those of brass, it is ideally suited to the manufacture of wheels, bridges and base plates.

PLATINUM – Although a tiny number of jewellery items made in pure (more than 80%) platinum between the first and fourth centuries AD have been found in Ecuador, the history of this metal really began in 1741 with the arrival of a sample in Europe.

Its first mechanical application was the creation of a watch with the staff and pallets of the lever escapement mechanism made in platinum, which was presented to Louis XVI in 1788. A few years later, Abraham-Louis Breguet fitted his grand self-winding complication, called the “Marie-Antoinette”, with an oscillating weight in the same metal. From the end of the nineteenth century, platinum was used in the manufacture of jewellery watches.

SILICON was isolated for the first time in 1823 by Jöns Jacob Benzelius, a Swedish scientist considered to be one of the founders of modern chemistry. In 1854, Henri Sainte-Claire Deville obtained monocrystalline silicon, which since then has been used in microelectronics.

Although Edward John Dent made a balance spring in glass – the ancestor of silicon escapements – in 1828, it was not until the early 2000s that this metalloid was used to make escape wheels, balances and levers, thanks to technological advances in plasma etching.

Low in density, resistant to friction and corrosion, nonmagnetic and requiring no lubrication, but generating high machining costs, it is a component of various alloys developed and patented by certain watchmakers.

SILVER – Known since Antiquity, silver is used in watchmaking, jewellery and silversmithing both as a precious metal and as silvered metal produced by electroplating. As an alloy made up of 92.5% of silver and 7.5% of another metal, it has the disadvantage of oxidising. It is a popular choice for flinqué dials and cases and is the metal best suited for gold-plating.

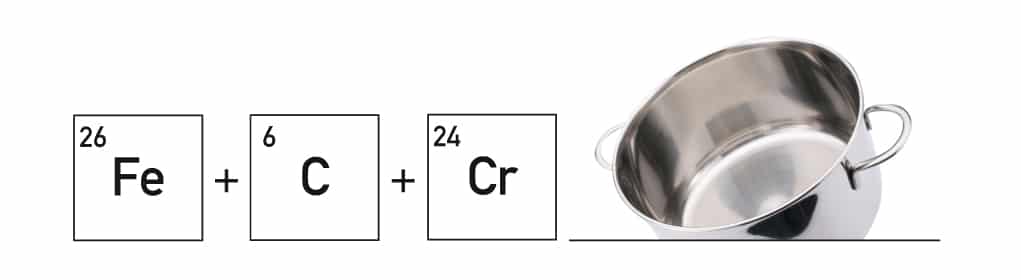

STAINLESS STEEL – The first corrosion-resistant alloys of iron and steel were cast in ancient times, as the Iron Pillar of Delhi, erected around AD400, testifies. However, they owed their properties to their phosphorous content and not to chrome, which is the current definition of stainless steel.

In 1911, it was demonstrated that the proportion of chrome in alloys affects their resistance to corrosion. Two years later, the English metallurgist Harry Brearley developed a steel containing 0.24 percent of carbon and 12.8 percent of chrome, which he named “rustless”. Subsequently renamed, it was the first officially designated “stainless steel”.

STEEL – Starting in the Iron Age, iron oxide was worked in bloomeries at a relatively low temperature. The resulting heterogeneous mass, or “bloom”, was then hammered to remove the slag. The blocks of metal produced in this way did not all have the same properties and at that time no distinction was made between iron, steel and cast iron.

In antiquity, the Greeks used cementation, a process that increased the amount of carbon in the iron, which hardened and turned into steel. For some people, the Iron Age actually began in mediaeval times, when it became necessary to shoe draught animals and the mounts of knights.

In twelfth-century Belgium, iron was obtained by refining an initial batch of cast iron to produce steel, among other things. In the Middle Ages, the term “steel” referred to alloys which, when heated red-hot, hardened on being quenched in water.

This process spread through Styria and Carinthia, then to Germany, Piedmont and Hungary. In the second half of the thirteenth century, metallurgy workshops were set up near to water courses, the hydraulic force operating bellows that raised the temperature of the furnaces and, through camshafts, worked increasingly heavy hammers at a steady rhythm to remove slag from the metal. In the fifteenth century, blast furnaces became common all over Europe.

They made it possible to attain temperatures of around 1,600°C and produce molten iron which, when refined, formed natural steel. It was only in the late eighteenth century that the carbon content was used to distinguish between iron, steel and cast iron. Today, industrial iron and mild steel contain less than 0.005 per cent, steel between 0.05 and 2.01 percent, and cast iron between 2.1 and 6.67 percent.

TITANIUM – Discovered in 1791 by the English mineralogist William Gregor and produced by the American industrialist Matthew Albert Hunter from 1910, titanium has the advantage of being biocompatible, which means that it has the ability to withstand bodily fluids. Both twice as light and twice as strong as stainless steel, it meets the requirements of sports watch cases, as well as those for repeater and chiming watches.