Alarm wrist watches are coming more into favour and among the principal makes are LeCoultre, Roamer, Lanco, Pierce, Cyma, Favre-Leuba, Borel, Reusser, Nitella, Olma, Simex, Friedli, Fulton, Mediator and Aerina.

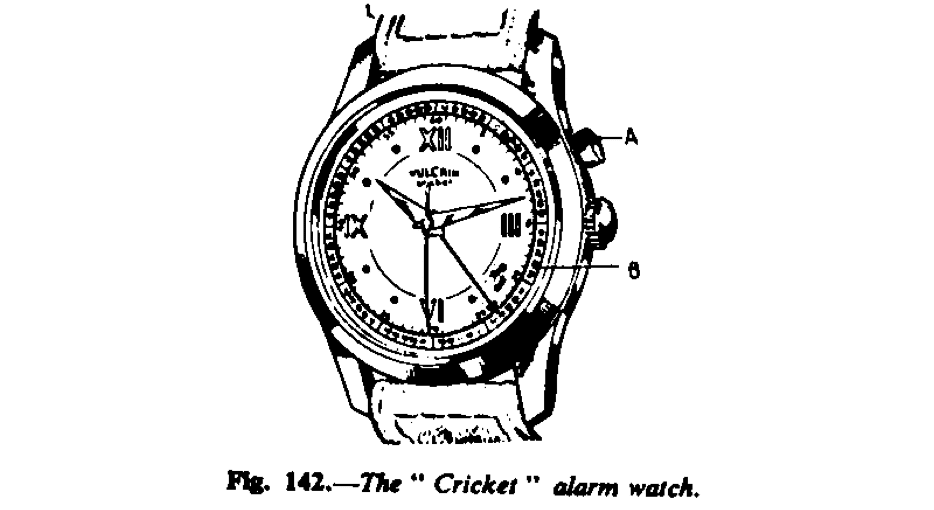

That selected for examination is by the Vulcain Watch Co., of La Chaux-de-Fonds, Switzerland. They have a wrist watch they have named the “Cricket” no doubt because of the cricket-like noise it makes when the alarm is sounding. The fundamental principle of the alarm work is much the same as the ordinary alarm clock, but there are one or two refinements. The Vulcan was the first wrist alarm to be made.

To Set the Alarm

The movement is fitted with two barrels, one for the going train and the other for the alarm. The winding button is turned anti-clockwise to wind the alarm train. The minute and hour hands are set in the conventional manner by withdrawing the winding button. It will be found that the hands can be set in one direction only-forwards, by turning the winding button anti-clockwise.

To set the alarm hand, press the push piece A (Fig. 142). This will cause the winding button to withdraw and the alarm hand ca be set by turning the winding button in a clockwise direction; the alarm hand rotates in an anti-clockwise direction. If the winding button is turned in the opposite direction to that stated, both when setting the hands or the alarm hand, it will be found to be quite free; no contact is made with the mechanism. When the alarm hand has been set, press the winding button back into position and this will automatically release the alarm setting mechanism and the push piece A will jump outward into its normal position.

When the alarm mainspring is fully wound the alarm will sound for 25 seconds and, if desired, it may be stopped by pressing the push piece A half-way in. If the alarm spring is wound and it is desired not to use the alarm at all press the push piece. A half-way in. This will cause the winding button to jut out half-way to the hands set position; in this neutral position the winding button is free and idle and drives no gears. To make the alarm operate, press the winding button in, which releases the alarm and the push piece will jump outward. Also, if the alarm mainspring is not wound at all, pressing the push piece half-way in will prevent the hammer from striking the sounding pice. On no account should the push piece A be pulled out manually : it is operated through the winding button only. The alarm dial B is calibrated in 10-minute intervals to facilitate the accurate setting of the alarm.

Dismantling the Alarm Watch

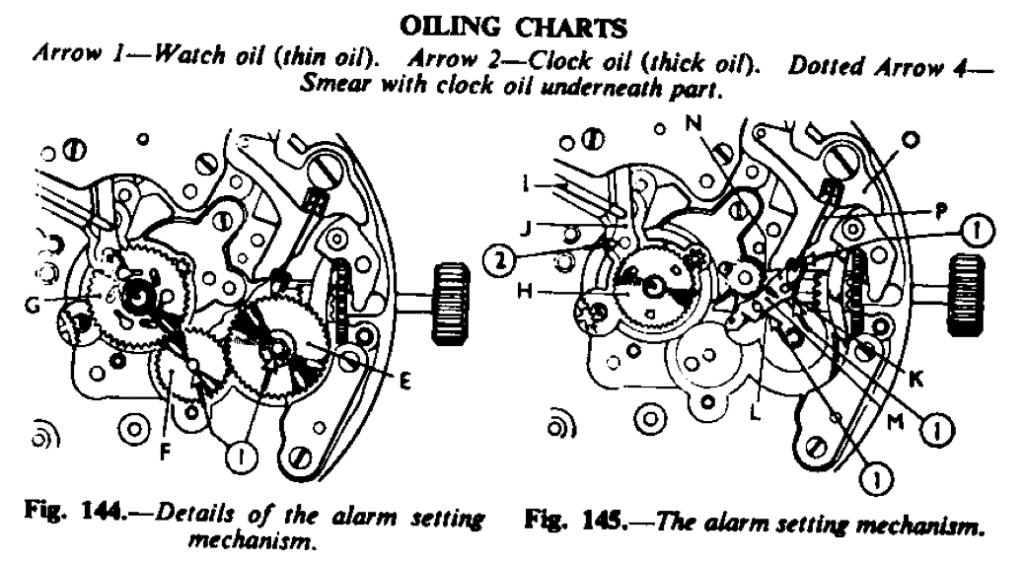

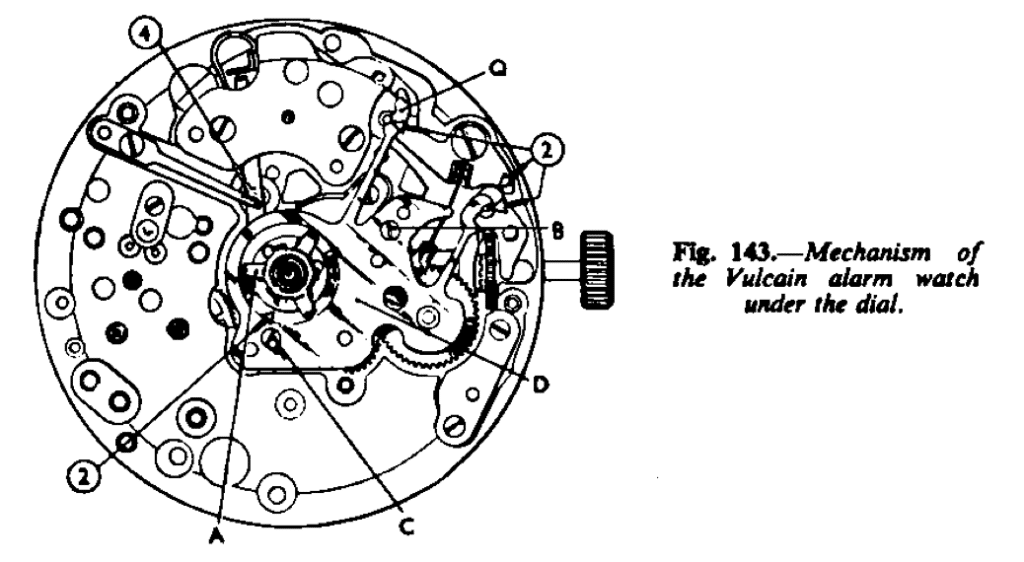

With the movement from its case, remove the hands and the dial. Turn the spring locking piece A (Fig. 143) a little to the left and it will spring up and away from the wheel it has been holding friction tight. Then unscrew the two screws B and C and lift off the pate D. The alarm setting wheel E and F (Fig. 144) can now be removed and then the alarm wheel G. It will be noted that the wheel H (fig. 145) has three square holes placed at unequal distances apart and from the centre. These can coincide with three projections from the underside of the alarm wheel G, but in on position only will they coincide and allow the hour wheel H to spring upward, by virtue of the spring I pressing upon the lever J. The tailpiece of the lever is then free of the alarm pallets and allows the alarm to operate. The object of the three projections is to ensure that no side pressure is exerted upon the cannon pinion and by this means the hour wheel is able to rotate freely.

When setting the hands, the castle wheel engages the wheel K, and this wheel engages the wheel L, which is fitted to the rocking arm M, and when the winding button is made to rotate anti-clockwise, the wheel N engages the intermediate wheel, and so the minute wheel and cannon pinion. If the winding button is made to rotate clock-wise the wheel L is thrown out of gear and the button rotates freely.

When setting the alarm hand, the push piece A, fig. 142, is depressed to its full extent and it contacts the lever O, Fig. 145, which forces the pull-out piece to the hand-set position and at the same time the spring P holds the rocking arm M to one side so that the wheel M engages the pinion of the wheel E, fig. 144. This wheel engages the wheel F, which in turn engages the alarm wheel G. The lever O is held in position while setting the alarm by the check-spring Q, fig. 143. It will be seen, therefore, that by depressing the alarm button the pull-out piece is automatically returned to its normal position.